Sustainability Report Q1 2022

THE

SUSTAINABILITY

REPORT: Q1 2022

Here at Ref, loving the planet is a year-round thing. That’s why sustainability is at the core of everything we do. We believe in focusing our efforts where we can make the biggest impact for our business and the planet. So we send out this report at the end of each quarter to show where we’re at in our four main areas of sustainability: People, Planet, Product, and Progress.

PEOPLE

Social responsibility

Diversity, equity, and inclusion

Community engagement & impact

PRODUCT

Better materials

Clean chemistry

Traceability

PLANET

Climate action

Resource efficiency

Low impact care

PROGRESS

Circularity

Sustainability reporting

& transparency

Packaging innovations

Here’s a look at what we’ve been up to since our last update:

PEOPLE

There are a lot of awesome people behind our clothes, and we’re responsible for ensuring safe, healthy, and equitable working conditions for all of them. We’re committed to being people-focused and will continue to grow and evolve our work in this area of sustainability. Because who makes your stuff, and how they’re treated, matters a lot.

Taking action

On March 25th, we offered paid time off to Refs around the world to join over 14 million people in the Global Climate March organized by Fridays For Future.

Today, we launched Climate Tees to help raise awareness and funds for climate action. 50% of the proceeds from every tee sold online will be donated to our friends at Canopy to support their work to protect forests, and 50% of the proceeds from every tee sold in our retail stores will be donated to a local environmental non-profit of the store teams’ choice.

Here are a few we chose:

- Ballona

- Earth Celebrations

- FABSCRAP

- GrowNYC

- Heal the Bay

- LA Compost

- Surfrider

- Tree People

- WeAct

- Wildlands Conservancy

Our Partners

Throughout our supply chain, we work with incredible partners who share our values of accountability, transparency, and sustainability. We know we’re not perfect, but we’ll always do our best to be transparent and keep pushing for better. We require all our direct cut, sew & finish manufacturing partners to adhere to our Code of Conduct (basically our requirements for ethical operations) to ensure fair labor conditions and fundamental labor rights. These include prohibiting child labor & forced labor, health and safety protections, and meeting or exceeding legal minimum requirements in the locales where they work. Our Code of Conduct references the FLA Workplace Code of Conduct, which is based on International Labor Organization (ILO) standards and internationally accepted good labor practices.

Our suppliers participate in independent, third-party social assessments to ensure fair, safe, and healthy working conditions and continuous improvement.

→ The process

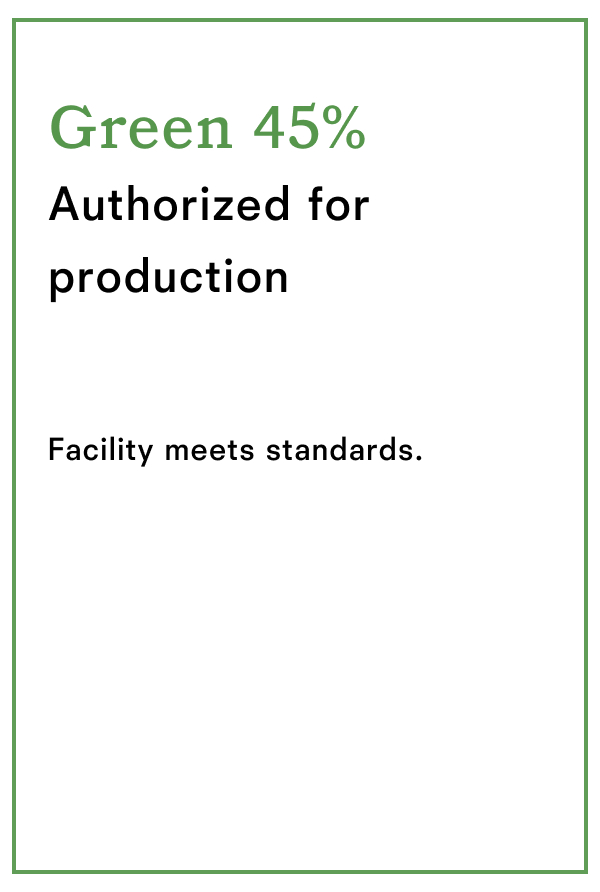

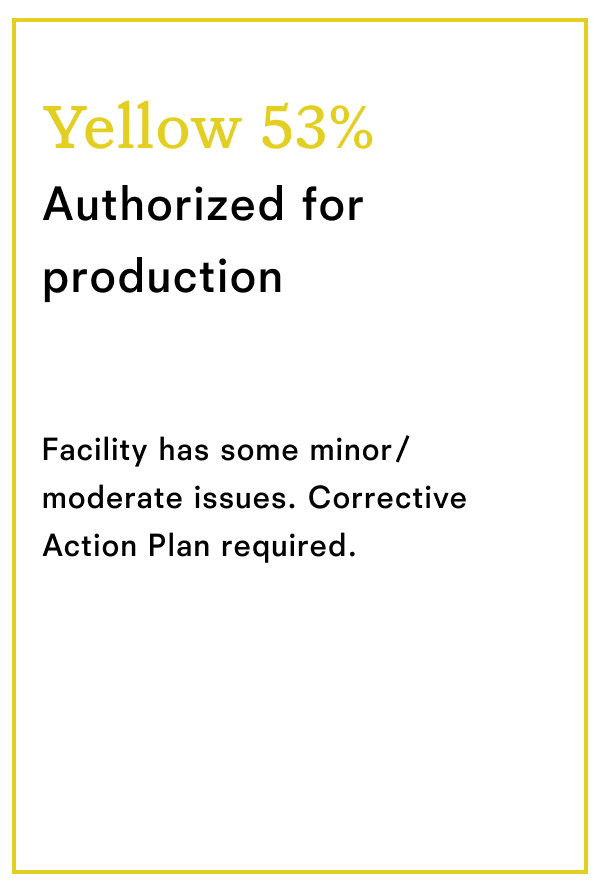

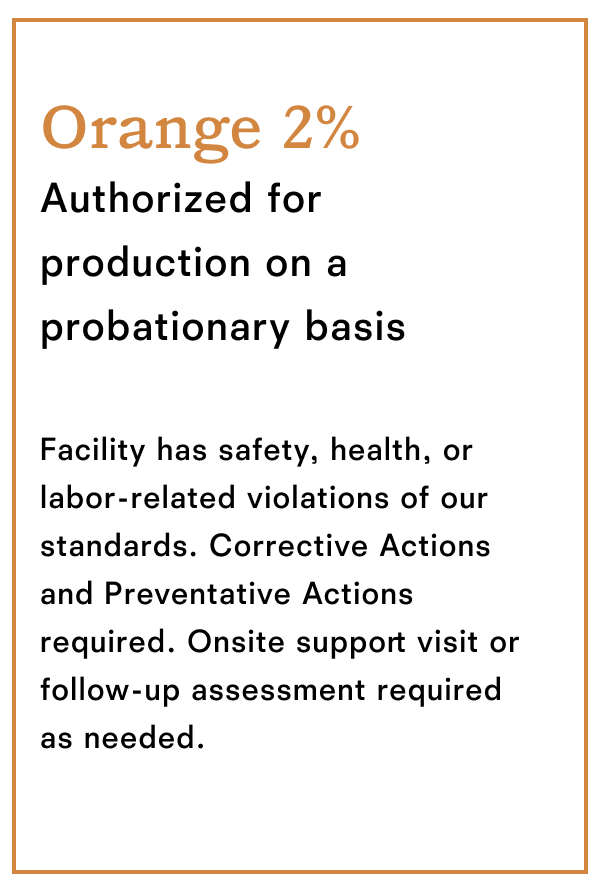

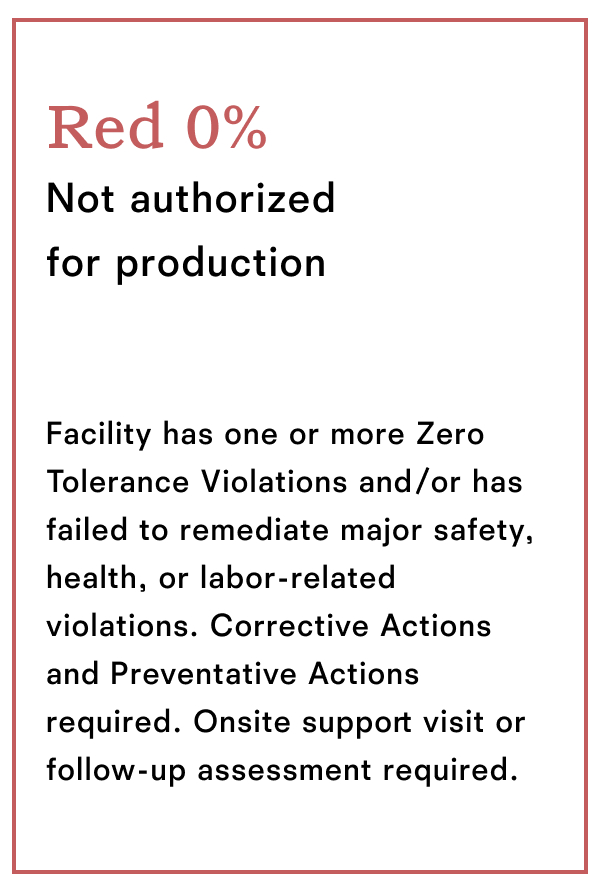

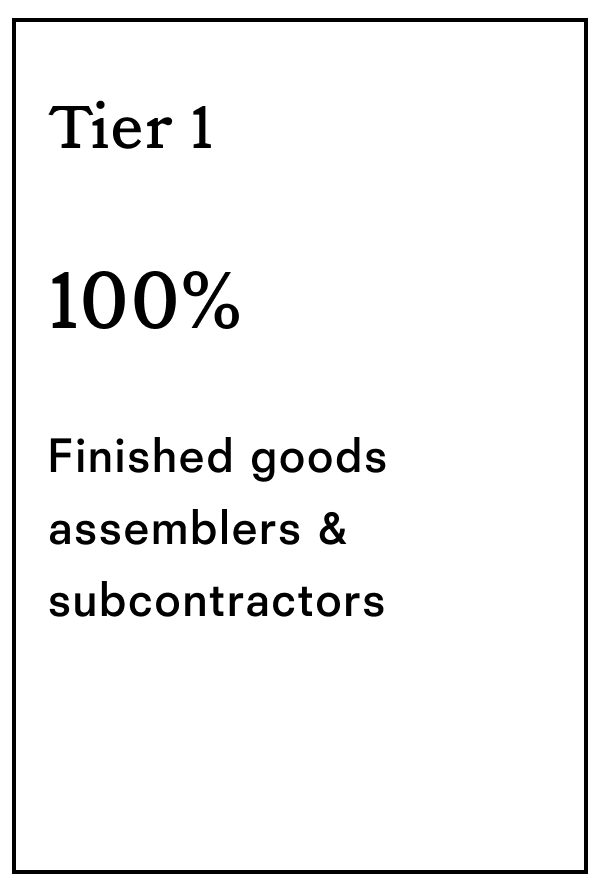

We use a color-coded rating system for our supplier audits. Our goal is to maintain a "Green" or “Yellow” rating for 95% or more of Tier 1 facilities (so our finished goods assemblers and contractors).

While some of our suppliers are in the Orange and Red tiers, we focus on partnering with suppliers to address the root cause, as our goal is always to maintain relationships with our partners and influence better practices.

Diversity, equity, and inclusion

We’re always working to create a culture of inclusivity and belonging, so this quarter we internally shared the Ref 2022 DEI Strategy with our teams. It includes a six-month look back at our actions and impact, along with an overview of where we’re heading next.

As we continue this important work, we will continue to share an in-depth update in our EOY report, which you can find right here. But we’ll keep you in the know with relevant news throughout the year.

PRODUCT

Your clothes go through a lot before they make it to you. We do the heavy lifting behind the scenes and focus on things like traceability, fiber standards, and clean chemistry to ensure we lessen the environmental and social impacts of our stuff so you can wear your values.

Clean Jeans

This month, we launched a capsule collection of denim made from fabric scraps recycled from the factory floor. We partnered with Strom, a fully vertical manufacturer, and Bossa, a mill making progress towards zero waste practices. The scraps were blended with cotton sourced from a climate positive farm and then woven into 20% recycled cotton and 80% regenerative cotton denim, cutting their carbon footprint by around 27% and water use by around 89% compared to regular jeans. They’re also traceable thanks to Fibretrace, which shows consumers denim’s entire lifecycle—from farm, to mill, to factory, to us. Strom and Bossa are leaders within denim innovation, so we’re super excited to bring their technology to the Ref Jeans our customers love and keep pushing the fashion industry forward.

All styles from this collection are also recyclable via RefRecycling and meet the Ellen MacArthur Jeans Redesign guidelines for garment durability, material health, recyclability, and traceability. These practices ensure jeans last longer, can easily be recycled, and are made in a way that is better for the environment and the people who make them.

Shop Circular Denim and read more about why it’s good for the Earth.

Fashion for Good

We joined Fashion for Good, the global platform working to drive systemic change in the fashion industry through innovation and collaboration. Through our partnership, we’ll focus on providing expertise and mentorship and piloting emerging technologies in raw materials, processing, traceability, and end-of-use amongst others. We’re excited to be a part of industry-wide collaboration and collective investment that helps us do our work and support our mission.

TRACEABILITY

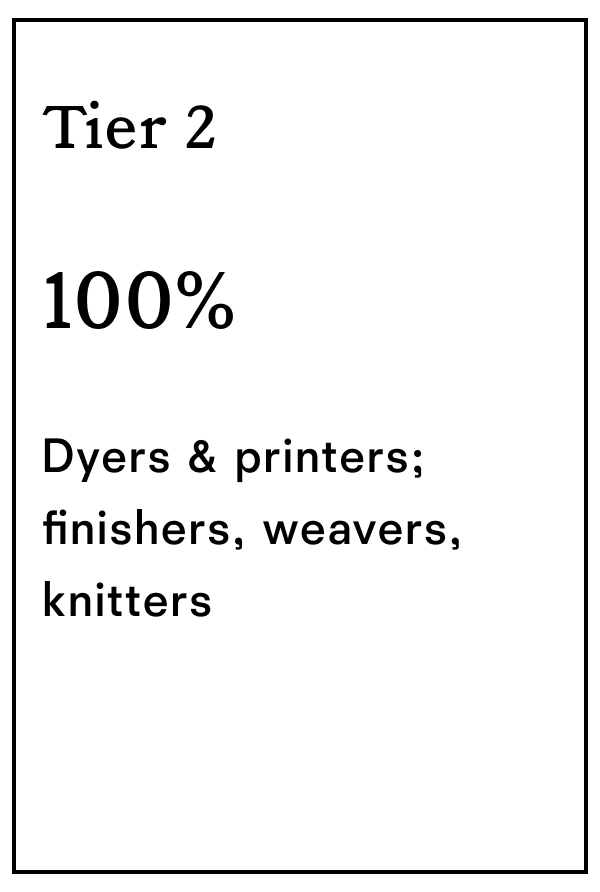

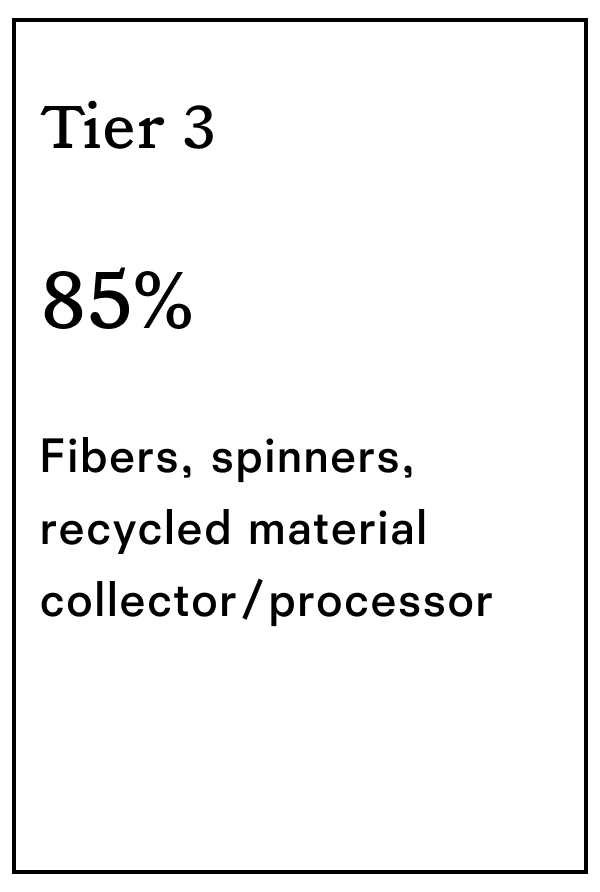

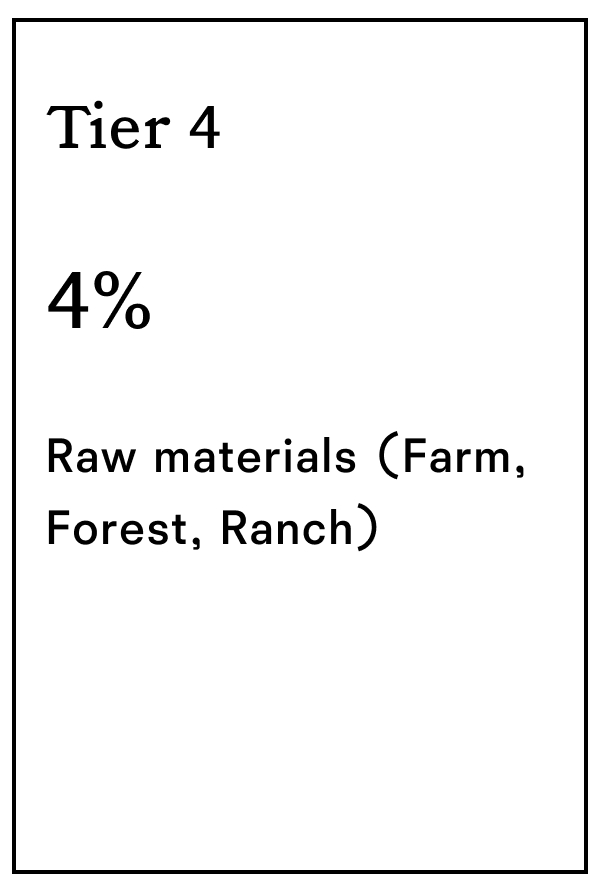

Traceability is about knowing exactly where our stuff comes from. We want to be able to answer “who made our clothes” at every level of the supply chain. Our goal is to reach 100% traceability1 down to the farm level for all of our animal-derived materials by 2025. Supply chains are fragmented and complex, so we’re focusing on building relationships from the ground up and digging deeper into where our stuff is grown so we can take accountability for responsible practices all the way through our supply chain.

1 Traceability is calculated by total fabric yardage for apparel and by upper fabric volume for shoes Q1 2022. This excludes all deadstock materials.

Here’s where we’ve made our stuff in Q1:

We’re committed to making clothes with a smaller environmental impact in places that treat workers well. We provide resources and support to help our partner factories align with our goals, achieve our standards, and move beyond compliance.

→ Learn more about our factories

Los Angeles |

32.3% |

China |

47.8% |

Turkey |

11% |

Mexico |

4.9% |

Brazil |

3.3% |

India |

0.7% |

*Based on % volume shipped in Q1

FIBER STANDARDS

Up to 2/3 of our sustainability impact happens at the raw materials stage—before the clothes have actually been made.

The materials we use are a major driver of the total impact of our products. We have our own fiber standards that are as holistic as possible, taking into consideration water input, energy input, land use, eco-toxicity, greenhouse gas emissions, human toxicity, availability, and price. We also look at garment care implications, like microfiber shedding. We updated our fiber standards to include a few new fibers and more of the components we use in our shoes. Our goal is to have 100% of our fabrics be from recycled, regenerative, or renewable materials by 2025.

92% of our fabrics are from recycled, regenerative, or renewable materials2

96% of our fabrics meet our A/B ratings2

→ Learn more about Ref fiber standards

2 Fiber performance is calculated by total fiber volume usage Q1 2022. Leather and deadstock are measured by total material volume usage. Percentages have been rounded up.

CLEAN CHEMISTRY

We want our products to be safe for everyone and everything they touch. That is why we partner closely with our printers, dye houses, and tanneries to ensure they are using chemical, water, and energy resources responsibly when making our stuff. We are aligned with the Zero Hazardous Discharge of Chemicals (ZDHC), an industry collective dedicated to holistic and effective chemical management in the production of textiles through the adoption of their Manufacturing Restricted Substances List (MRSL)–a list of chemicals that should be restricted in the production of materials. Our goal is to have 100% of our materials come from suppliers with clean chemistry certifications or ZDHC conformance by 2025. We joined bluesign® as a system partner in 2021, and with their help are assessing our supply chain on how we can best meet our clean chemistry goals.

47% of our dyers and printers have a clean chemical certification3

3 Percent of clean chemical certifications or ZDHC MRSL conformance of Level 2 and higher for dyers, tanneries, and printers is calculated by total fabric yardage for apparel and upper fabric volume for shoes Q1 2022. This excludes all deadstock materials.

PLANET

Making clothes has a big impact on people and the planet. We keep our true costs in mind when making any decision by tracking our product and company-wide environmental footprint.

SEXY MATH

RefScale calculates our environmental footprint by adding the pounds of carbon dioxide emitted, gallons of water used, and pounds of waste generated by our business. Then we determine how much Reformation saves compared to conventional clothes bought in the US. The whole equation follows the lifecycle of our stuff—everything from growing textile fibers and making fabric, dyeing, transporting materials, manufacturing, packaging, shipping, garment care, and even recycling clothes when you’re done with them.

We are a Climate Neutral Certified company which means we partner with Climate Neutral each year to measure our carbon emissions, offset 100% of our footprint, and implement strategies to reduce our emissions.

Carbon intensity of our products

CO2e lbs per unit of clothing

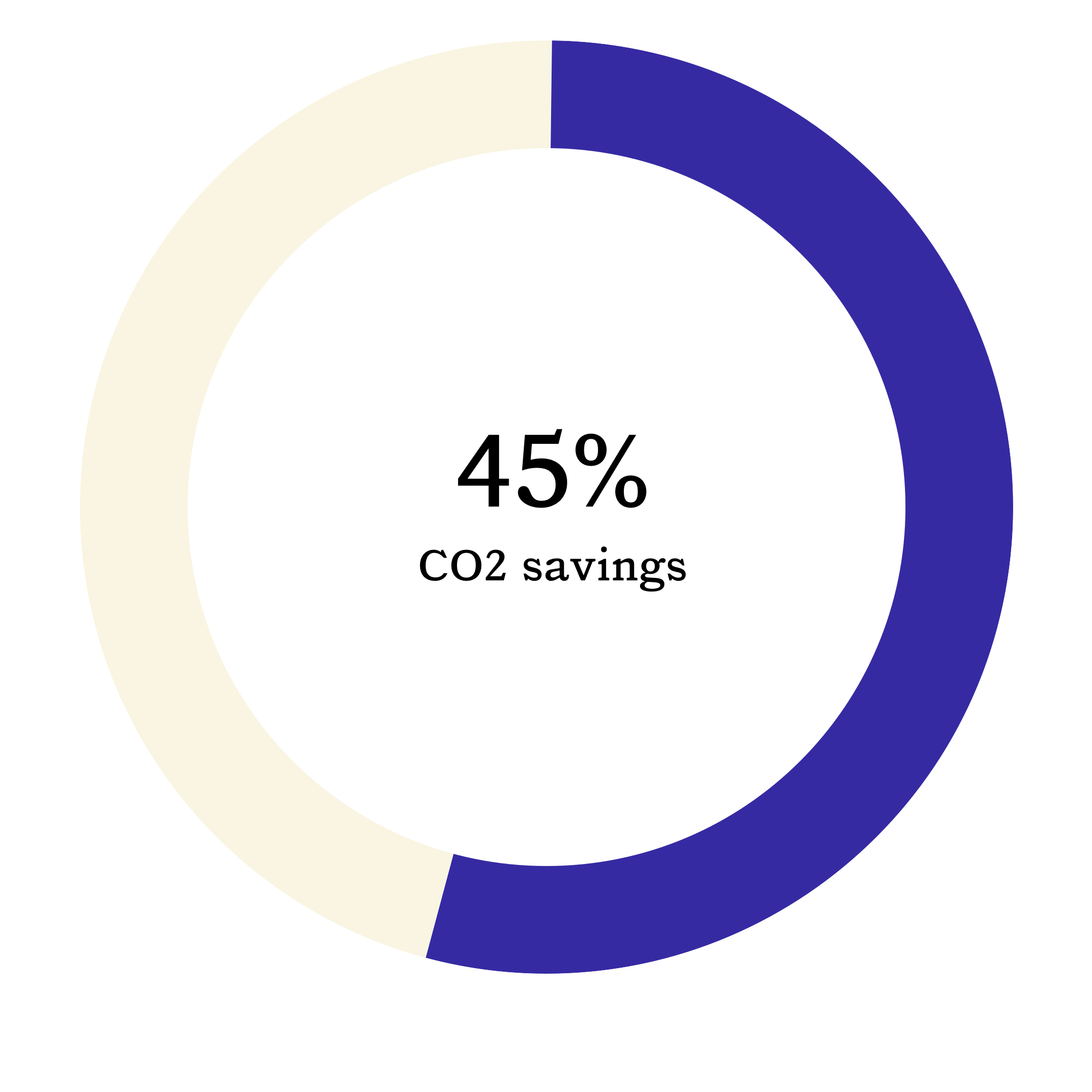

2022 Year to Date total footprint

Carbon dioxide (Metric tons)

Ref footprint: 8,512

Conventional footprint: 15,527

Savings: 7,015

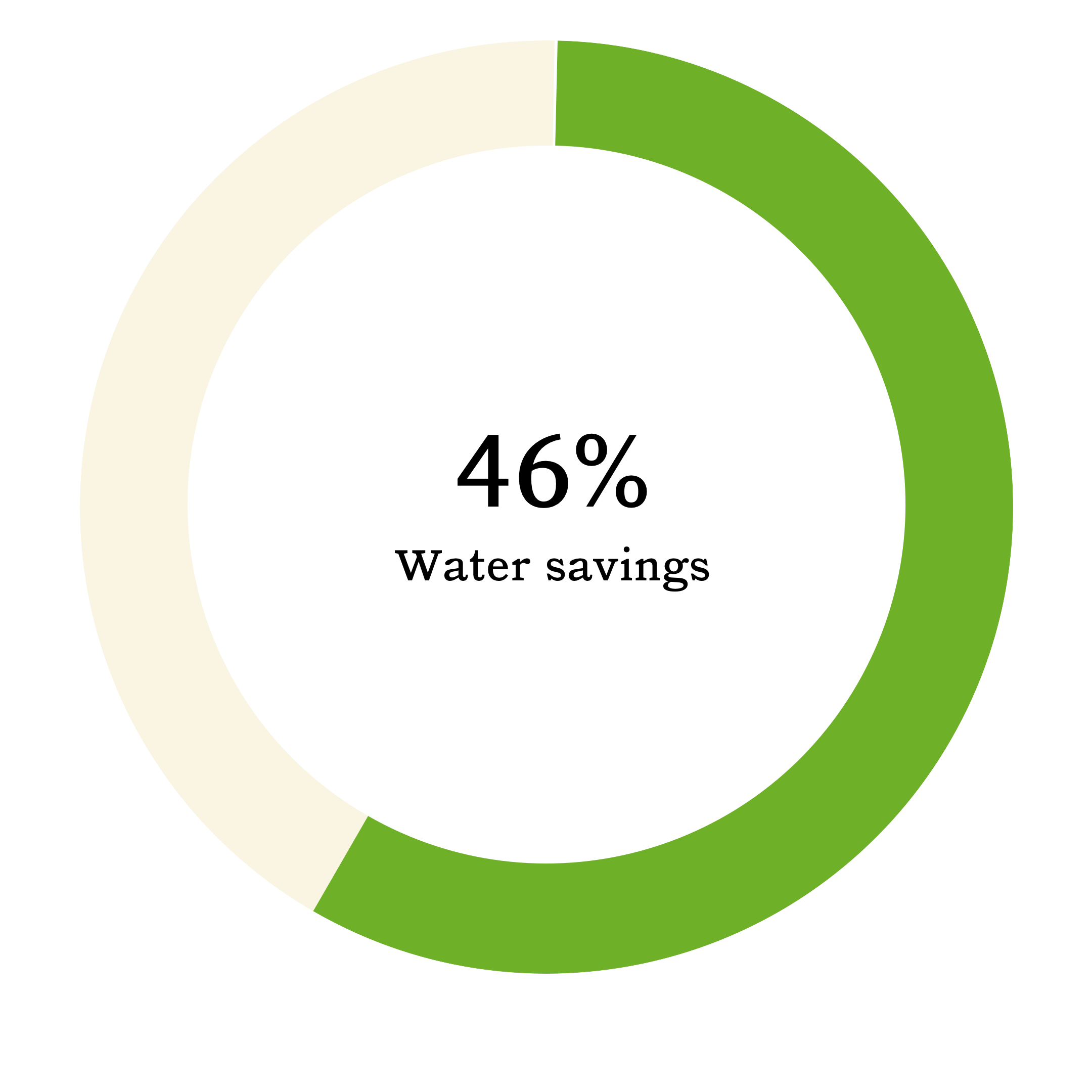

Water (M gallons)

Ref footprint: 1,454

Conventional footprint: 2,708

Savings: 1,254

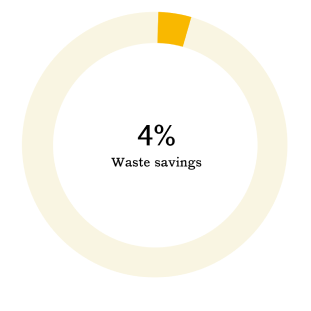

Waste (Metric tons)

Ref footprint: 625

Conventional footprint: 663

Savings: 38

The fashion industry is responsible for up to 10% of global carbon emissions and is on track to double that by 2050. That’s why we made a commitment to be Climate Positive by 2025. We’re defining this as meeting science-based reduction targets and removing more emissions than we produce. Targets are considered “science-based” if they are in line with the level of decarbonization required to keep global temperature increase below 1.5°C compared to pre-industrial temperatures, as described by the Intergovernmental Panel on Climate Change (IPCC). This quarter we had our targets confirmed and validated by the Science Based Target initiative.

Our Science Based targets:

We commit to reduce absolute scope 1 and 2 GHG emissions 42% and scope 3 emissions by 48% per value added by 2030 from a 2021 base year. We also commit to continue annually sourcing 100% renewable electricity through 2030.

Basically, as we grow, we’ll work to cut our emissions by ~half across our operations and within our supply chain.

PROGRESS

We have a lot of work to do to create a fashion system that is truly circular. In order to push sustainability forward, we challenge our efforts and don’t shy away from hard problems. We’re committed to investing in the future, and we’ll always be transparent about our progress.

WE GET AROUND

Circularity is all about designing out waste and keeping materials in use. Decisions at the design stage about what type of fiber to use or material composition can all affect what recycling options are available for the final product. The technology and infrastructure exists to recycle some materials back into fiber, but it’s not yet available for everything. We’re setting a goal to have 100% of our fabrics be fiber-to-fiber recyclable by 2025 to motivate us to design into fabrics that have potential for circularity and to build more partnerships with recyclers to make it easier to keep all of our stuff around.

13% of our fabrics are fiber-to-fiber recyclable4

4 Percent of fiber-to-fiber recyclable fabrics is calculated by total fabric yardage for apparel and upper fabric yardage for shoes Q1 2022. This excludes all deadstock materials.

RefRecycling

The U.S. alone throws away over 16 million tons of textiles a year, most of which sits in landfills indefinitely. We’ve been recycling and reusing our stuff since 2015, and now we’re taking a big step towards developing a fully closed-loop system with the launch of RefRecycling, powered by SuperCircle. This is the first and only program to offer fiber-to-fiber recycling, where well-worn Ref clothing is broken down into fibers that can be used to make new Ref clothing. Less than 1% of clothes are recycled back into new garments, so we’re working hard to build restorative systems that let us make new Ref out of old Ref with as few new materials as possible. Through fiber-to-fiber recycling, well-worn Reformation clothing is broken down into fibers that can be used to make new Reformation clothing. Since circularity is really great for the planet, it’ll also help us meet our commitment to be Climate Positive by 2025.

We’re starting by recycling our denim, sweaters, activewear, and shoes. Each product will be recycled into a different yarn based on its original materiality. Our shoes are currently downcycled into materials used for building and infrastructure, but we’re working on innovations to keep these materials in the fashion supply chain too.

To join us, drop off your well-worn Ref at any of our U.S. retail locations or request a shipping label online. Items are sent to our friends at SuperCircle, who aggregate these products and then send them to our preferred waste management partners to break them down into raw materials. As a thanks for keeping materials around you’ll get Ref credit for every item you send back.

United Nations Sustainable Development Goals

The fashion industry has a major impact on the global economy and the environment. That’s why we aligned our sustainability framework with the United Nations Sustainable Development Goals (SDGs) to make sure we’re tackling the most important issues like climate change and economic inequality.