Sustainability Report Q4 2022

Q4 2022

THE SUSTAINABILITY REPORT

Oversharing is kind of our thing. While most big companies just share quarterly earnings reports, we think we should all be accountable for more than that. So we tell you more than you’ve ever wanted to know about your clothes. This time, we’re telling you about all the progress we made in the last few months, and we'll still publish an annual report on all things 2022 once all our data is in. Until then, here’s an update on how we’re doing in our four main areas of sustainability: People, Product, Planet, and Progress.

There are a lot of awesome people behind our clothes, and we're responsible for ensuring safe, healthy, and equitable working conditions for all of them. We’re committed to being people-focused and will continue to grow and evolve our work in this area of sustainability. Because who makes your stuff, and how they’re treated, matters a lot.

Our Partners

Throughout our supply chain, we work with incredible partners who share our values of accountability, transparency, and sustainability. Nobody’s perfect, but we’re working towards it and prioritizing transparency every step of the way. We require all our direct cut, sew, and finish manufacturing partners to adhere to our Code of Conduct (basically our requirements for ethical operations) to ensure fair labor conditions and fundamental labor rights. These include prohibiting child and forced labor, implementing health and safety protections, and meeting or exceeding legal minimum requirements in the locales where they work. Our Code of Conduct references the FLA Workplace Code of Conduct, which is based on International Labor Organization (ILO) standards and internationally accepted good labor practices.

Our suppliers participate in independent, third-party social assessments to ensure

fair, safe, and healthy working conditions and progress over time.

→ The process

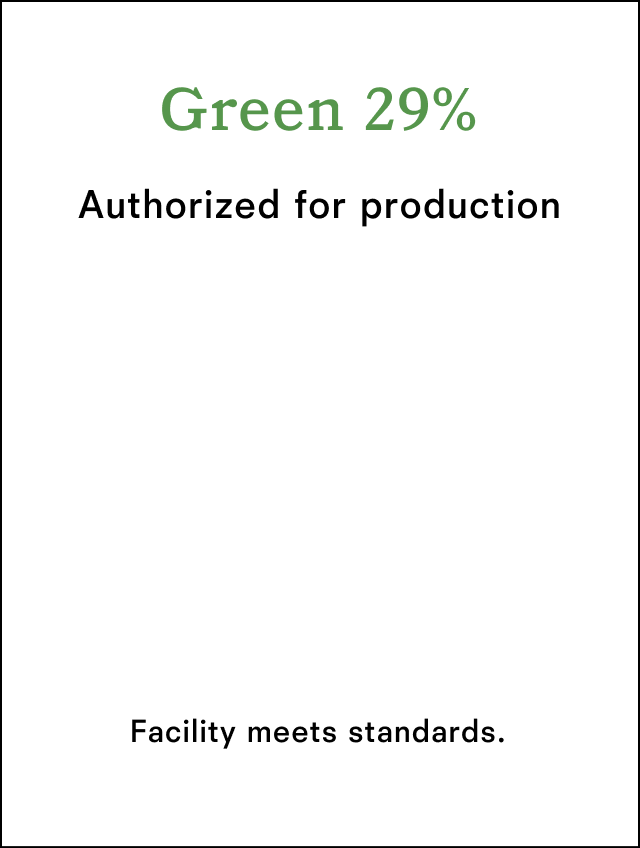

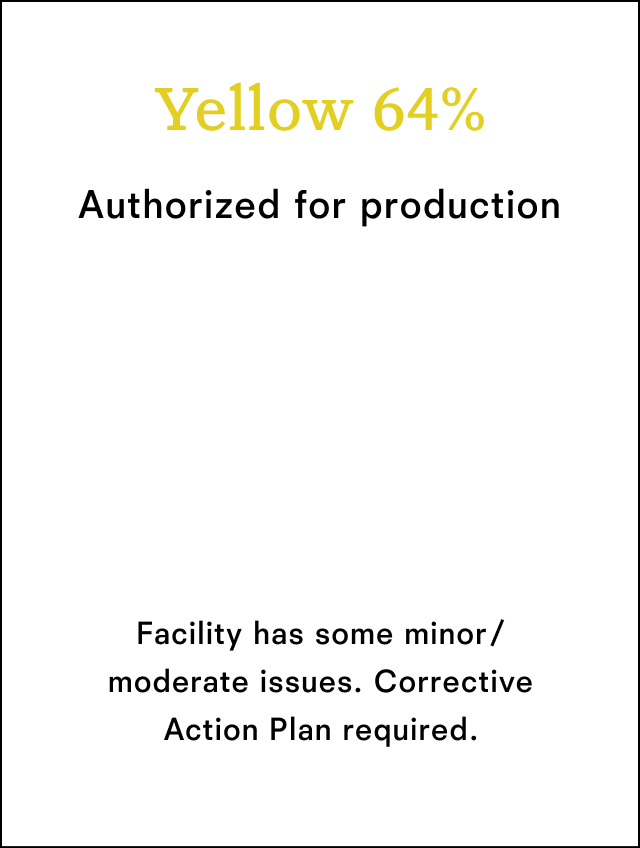

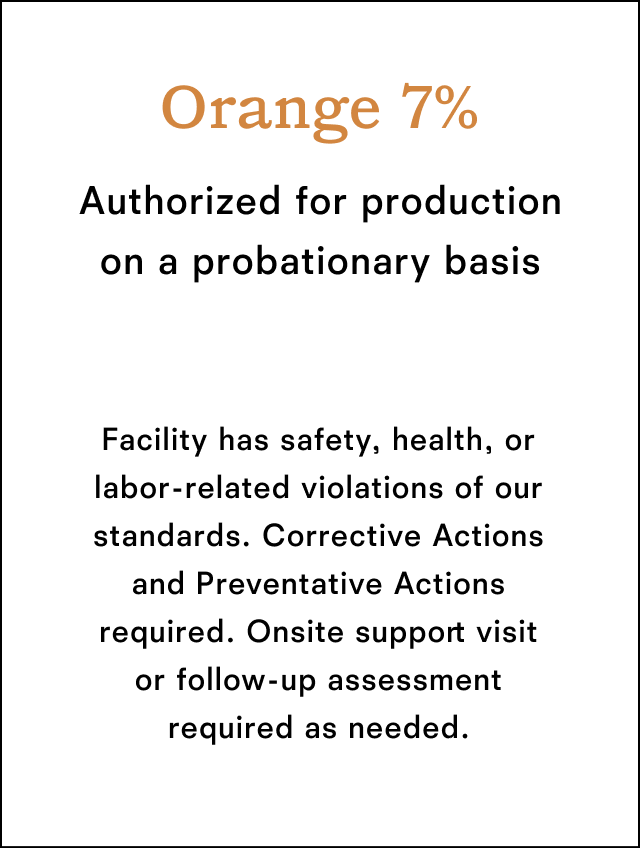

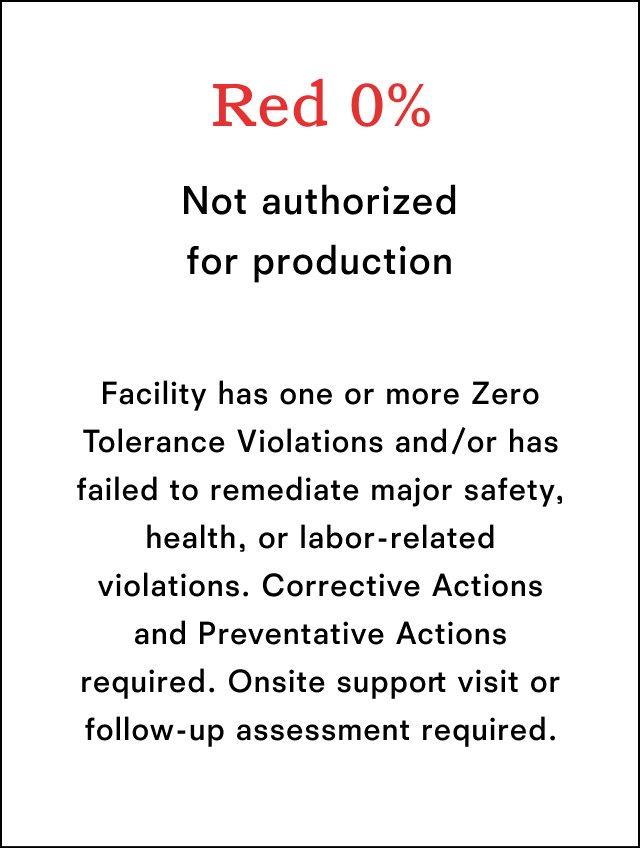

We use a color-coded rating system for our supplier audits. Our goal is to maintain a “Green” or “Yellow” rating for 95% or more of Tier 1 facilities (our finished goods assemblers and contractors). While some of our suppliers are in the Orange tier, we’re working with them to find solutions so we can maintain relationships and influence better practices.

The more you know

Each year we ask our employees to tell us about working at Ref through an anonymous engagement survey. It focuses on all aspects of their employee experience, including questions on DEIB. This year, we were incredibly proud of the improvement in the following two categories: Diversity - up 12% over our 2021 survey, and Inclusion - up 5% over our 2021 survey results. After hiring our SVP of Talent Acquisition and DEIB, we have continued our investment in programs, process improvement, education and awareness. What we continue to share with our employees is that DEIB is not a one-time goal or initiative, but an ongoing and continuous effort as an organization to support the ever-changing and dynamic needs of our teams. We will continue to survey our employees to understand their perceptions and feedback.

Positive feedback is super encouraging, but we still have work to do, and we’ll focus our efforts on DEIB initiatives and programs. So we launched a new partnership with the experts at Paradigm this quarter and completed an initial DEIB assessment. We’ll continue to work with them to better understand how we can level up our DEIB efforts.

We’ve kept up our work with external partners that are committed to advancing DEIB in the workplace. Our DEIB leader is a mentor for Creatives Wants Change, an organization that works to cultivate Black creative talent beginning in high school and into early professional development. We’re doing the work today to make tomorrow way better.

This quarter, our People leaders trained more than 120 Refs, in English and Spanish, on unconscious bias and micro-messaging. The training is all about digging into communication and its impacts. We also launched DEIB Office Hours, where employees can get specific, personalized help from our People team.

Our new Culture Committee members kept up our DEIB work, recognizing Hispanic Heritage Month, Native American Heritage Month, and International Migrants Day with dedicated resources and other programming to make everyone at Ref feel supported and seen.

Taking action

Voting is a big way to advocate for the rights of people and the planet, so we got out the vote with our Ref team all over the U.S. during the 2022 midterm elections. Through Reclaim Our Vote, a non-partisan voter outreach campaign, we sent more than 1,200 handwritten postcards to empower voters in states with documented voter suppression. We always give employees time off to vote and volunteer and we tracked over 300 volunteer hours as a team in 2022.

We also joined forces with like-minded brands and labor unions

and showed our support for the Fashion Sustainability and

Social Accountability Act, aka the Fashion Act.

If passed, the strengthened bill would hold fashion brands doing business in NY accountable for their impact

on people and the planet. We’re into this because it's an important signal of what consumers want from the industry

and gives us a chance for us to raise the standard. If it gains traction in New York, it will be a significant step

toward a truly progressive future.

People SDGs: 5 Gender Equality, 8 Decent Work & Economic Growth, 10 Reduced Inequalities, 12 Responsible Consumption & Production, 17 Partnerships for the goals

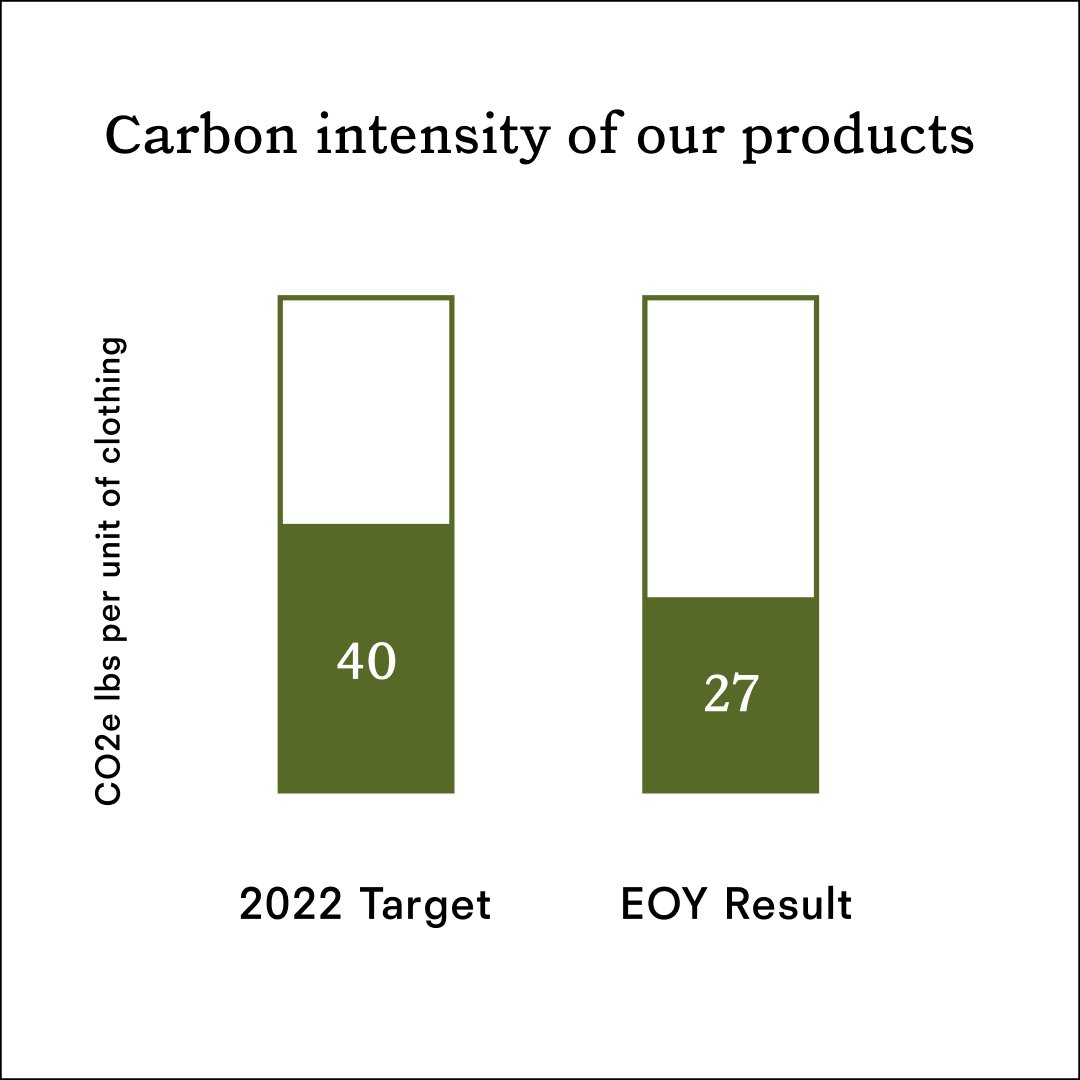

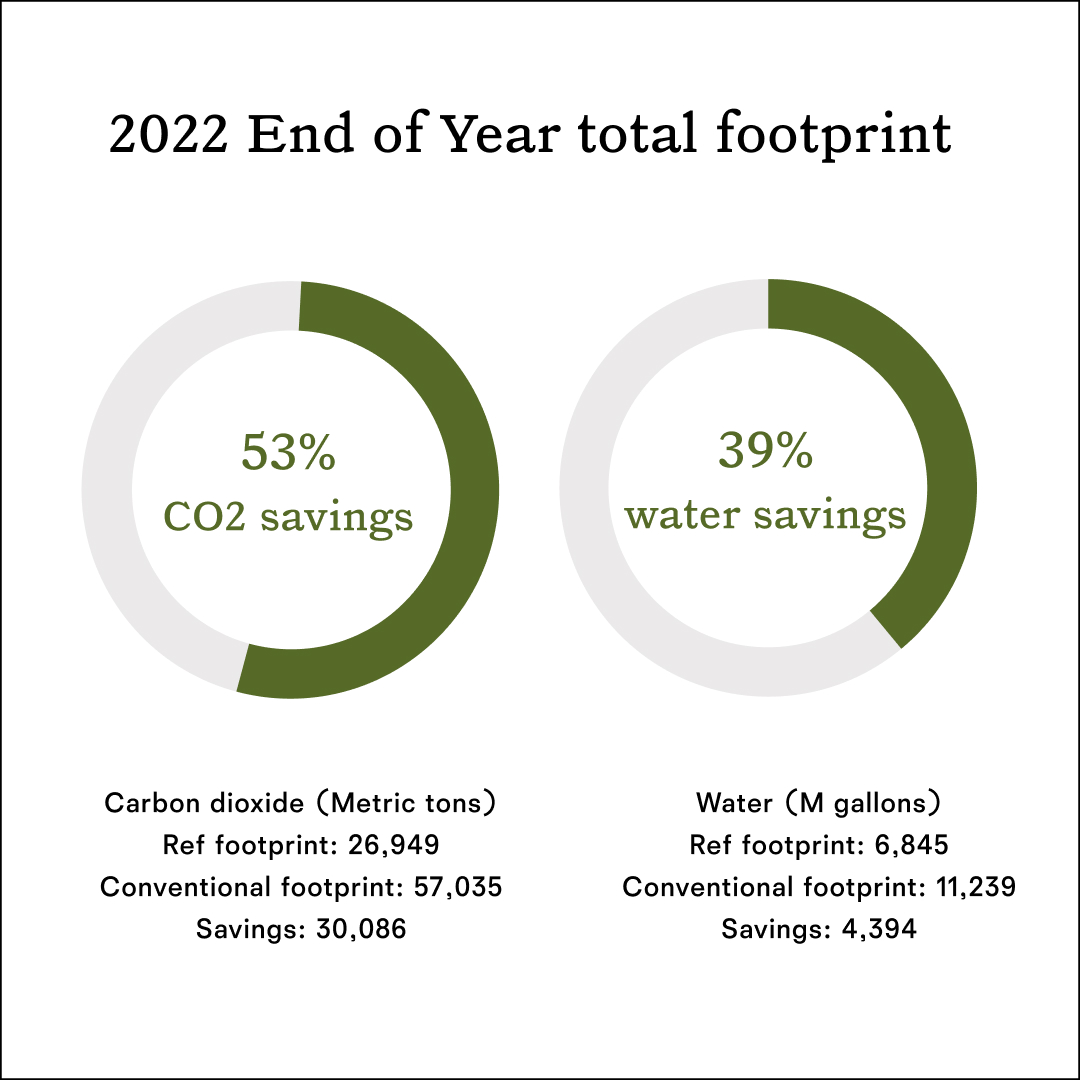

Making clothes has a big impact on people and the planet. We keep our true costs in mind when making any decision by tracking our product and company-wide environmental footprint.

We are a Climate Neutral Certified company, which means we partner with Climate Neutral each year to measure our carbon emissions, offset 100% of our footprint, and work on reducing our emissions.

The fashion industry is responsible for somewhere between

carbon emissions

and is on track to

That’s why we made a commitment to be Climate Positive by 2025. We’re defining this as meeting our science-based reduction targets and removing more emissions than we produce1.

1 Targets are considered “science-based” if they are in line with the level of decarbonization required to keep the global temperature increase below 1.5°C compared to that of pre-industrial temperatures, as described by the Intergovernmental Panel on Climate Change (IPCC). It’s a lot of info, but the good news is our targets are officially confirmed and validated by the Science Based Target Initiative.

We commit to reduce absolute

scope 1 and 2 GHG emissions by 42% and scope 3 emissions by 48% per value added by 2030 from a 2021 base year.

Basically, as we grow, we’ll work to cut our emissions by about half across our operations and within our supply chain.

The material innovations we launched in 2022 are helping us take big steps toward our Climate Positive commitment. We talk about them a lot because we think they're the future of fashion and will help create real changes in the industry, and our planet, if we work together. Some of our progress was covered by Fast Company last quarter, but instead of just bragging about it, we want it to inspire customers, brands, and the fashion industry to explore how they can take these solutions to scale ASAP.

Factory forward

determine up to

impact of your clothes.

Then, we determine how much Reformation saves compared to conventional clothing bought in the U.S. The whole equation follows the lifecycle of our stuff—everything from growing textile fibers and making fabric, dyeing, transporting materials, manufacturing, packaging, shipping, garment care, and even recycling clothes when you’re done with them.

Planet SDGs: 6 Clean Water & Sanitation, 12 Responsible Consumption & Production, 14 Life Below Water, 15 Life on Land

Your clothes go through a lot before they make it to you. We do the heavy lifting behind the scenes and focus on things like traceability, fiber standards, and clean chemistry. This reduces the impact of our stuff and lets you wear your values.

Cool Wool

We’re staying warm in the cutest way possible and getting closer to achieving our goal of having 100% of our fabrics be from recycled, regenerative or renewable materials by 2025 with our launch of coats made with MWool®. Manteco® is an Italian textile mill that's been recycling since the1940s. MWool® is a low-impact, premium, recycled wool made by mechanically recycling industrial waste, pre-consumer scraps, and post-consumer garments. MWool® eliminates the need to use new wool and is a fully circular fabrication with zero waste. Not to brag.

We love how the wool gets its color, too. Manteco® uses no added dyes and instead relies on the original colors from pre- and post-consumer garments used during the recycling process. Using their proprietary process, they’ve developed more than 1,000 MWool® colors using way less water and chemicals.

Each stage of its production is also certified by the Global Recycled Standard (GRS) to verify recycled content in materials and products, so it’s all traceable and made in a way more climate-friendly way.

We love silk for looking fancy. But we don't love its big, not-so-fancy environmental footprint. It’s a “D-rated” fiber for us due to its energy, water, and chemical intensity, and we only use it if it's bluesign® or OEKO-TEX® certified.

To become Climate Positive by 2025, we’re making sure the materials we use reduce emissions and help us shrink our sourcing footprint. This means we have to basically stop using virgin silk in the next few years. We’ve been busy testing next-gen alternatives to replace silk that have similar qualities but are way more sustainable. We launched styles with Naia™ Renew, a silk alternative that we think has a lot of potential to help us make this transition. It’s produced in a closed-loop process from 60% sustainably sourced and renewable wood pulp and 40% hard-to-recycle waste materials that would otherwise end up in landfills, all adding up to a low carbon footprint, and a traceable circular fiber that's biodegradable and compostable.

Plus it feels and looks pretty much the same as virgin silk. There are still some tradeoffs, so we’ll be launching more silk-like fabrics this year–stay tuned.

We were tired of being cold in our Ref dresses so we did something about it. Teaming up with the technical outerwear specialists at Canada Goose, we made a limited-edition, but forever-wearable, collection featuring the warmest stuff around. It featured vintage-inspired Ref flair plus 100% recycled nylon and filled with responsibly sourced down.

Bringing together our sustainability ethos and Canada Goose's HUMANATURE platform, the entire collection was made to wear forever. So you can pass it down to your kids and brag about how hot you looked scaling that mountain or whatever. So, to recap, we shared our mission of bringing sustainable fashion to even more people with a whole new wardrobe category and some friends at Canada Goose.

Up to 2/3 of the environmental impact of our stuff happens at the raw materials stage—before the clothes have actually been made.

The materials we use play a major role in the total impact of our products. We have our own fiber standards that are as comprehensive as possible, taking into consideration water and energy inputs, land use, eco-toxicity, greenhouse gas emissions, human toxicity, availability, and price. We also look at garment care implications like microfiber shedding and the potential for circularity.

93% of our fabrics meet our A/B ratings, and 73% are from recycled, regenerative, or renewable materials2

→ Learn more about Ref fiber standards

Our highest fiber ratings are basically the best materials around that we want to use all the time. But, to meet our Climate Positive and circularity goals, we’re getting even more specific about what we use to make our stuff. By 2025, we want 100% of our fabrics to be from recycled, regenerative, or renewable materials. It means getting rid of some of our more traditional fibers, but it’s worth it to keep our stuff as sustainable as possible.

2 Fiber performance is calculated by total fiber volume usage YTD. Leather and deadstock are measured by total material volume usage. Percentages have been rounded up.

85% of our dyers and printers have a clean chemical certification3

We partner closely with our printers, dye houses, and tanneries to ensure they are using chemical, water, and energy resources responsibly when making our stuff because we want our products to be safe for everyone and everything they touch. Supply chains are hard and shifting partners means starting these relationships over again, which is why this number is lower than it was in our last report. Moving forward, we are committed to only partnering with suppliers who are taking a proactive approach to chemical management. We joined bluesign® as a system partner in 2021, and with their help, we’re assessing our supply chain to see how we can best meet our clean chemistry goals. We’re also aligned with the ZDHC–which stands for the Zero Discharge of Hazardous Chemicals. They’re an industry collective dedicated to comprehensive and effective chemical management in the production of textiles. Our goal is to have 100% of our materials come from suppliers with clean chemistry certifications or Level 2 ZDHC compliance by 2025.

3 Percent of clean chemical certifications or ZDHC MRSL conformance of Level 2 and higher for dyers, tanneries, and printers is calculated by total fabric yardage for apparel and upper fabric volume for shoes YTD. This excludes all deadstock materials.

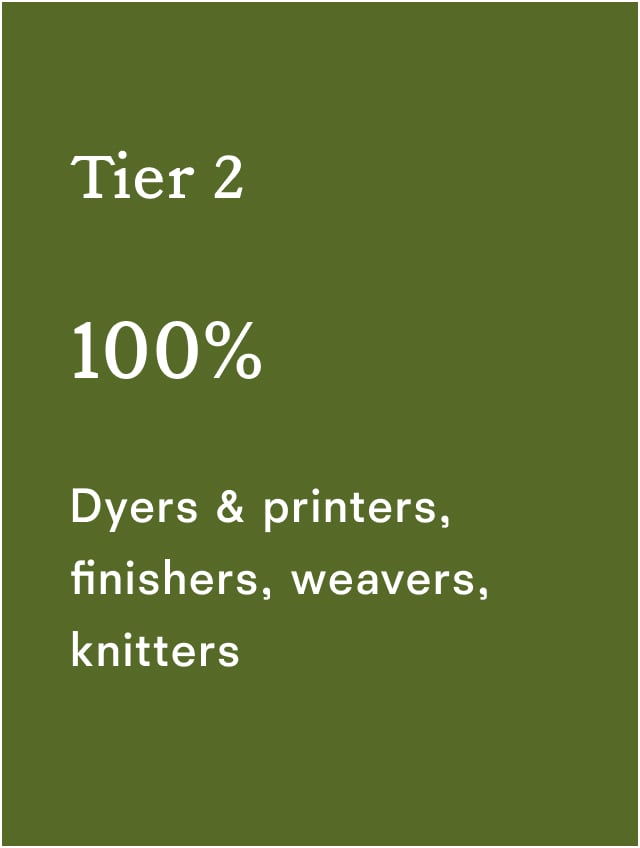

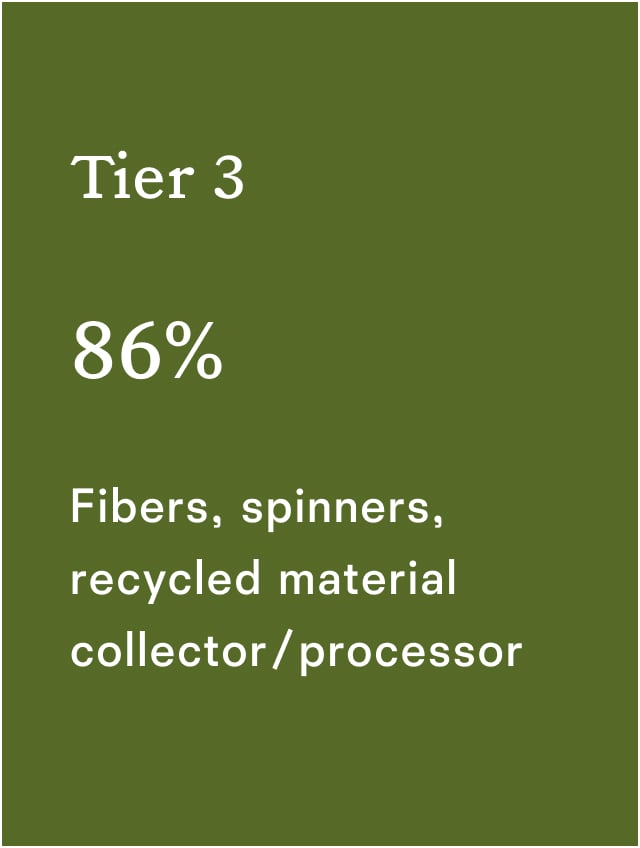

Traceability is about knowing exactly where our stuff comes from. We want to be able to answer “who made our clothes” at every level of the supply chain.

Our goal is to reach 100% traceability4 down to the farm level for all of our animal-derived materials by 2025. As we said, supply chains are complex, so we’re focusing on building relationships from the ground up and digging deeper into where our stuff is grown so we can take full accountability for everything we make.

Traceability Performance

Here’s where we’ve made our stuff so far this year:

*Based on % volume shipped YTD

| Los Angeles28.61% | Turkey8.29% | Mexico7.66% | Indonesia0.07% | Portugal0.02% |

| China50.87% | Brazil3.83% | India0.36% | Vietnam0.01% | Pakistan0.29% |

We’re committed to making clothes with a smaller environmental impact in places that treat workers well. We provide resources and support to help our partner factories align with our goals, achieve our standards, and grow with us.

→ Learn more about our factories

4 Traceability is calculated by total fabric yardage for apparel and by upper fabric volume for shoes YTD. This excludes all deadstock materials.

Product SDGs: 6 Clean Water & Sanitation, 12 Responsible Consumption & Production, 14 Life Below Water 15 Life on Land

We have a lot of work to do to create a fashion system that restores itself. In order to push sustainability forward, we challenge ourselves and don’t shy away from hard problems. We’re committed to investing in the future, and we’ll always be transparent about our progress.

Sustainable online

We have a new home for all things sustainability. Made for people who really want to geek out on our practices, make sure we’re actually doing everything we say we’re doing, or just stare at some pretty nature pictures, look no further. We’ll start updating it quarterly so you can see everything we’re up to in one place.

→ Go look

Decisions at the earliest stages of making clothes affect their end of life, like how you’ll recycle your Ref when you’re done wearing it. The technology and infrastructure exist to recycle some materials back into fiber, but it’s not yet available for everything. So we’re setting a goal to have 100% of our fabrics be textile-to-textile recyclable to motivate us to design only using fabrics that have potential for circularity. Because why would you ever want to throw this away. We’re also building more partnerships with recyclers to make it easy to keep our stuff around.

15% of our fabrics are textile-to-textile recyclable5

Way before your old Ref stuff needs to be recycled though, we’re testing out a way to keep our clothes wearable for longer by helping customers find the perfect fit. With our friends at Hemster, we’re piloting a program to understand how we can offer simple, custom alterations that would extend the lifespan of a garment and keep it in rotation season after season. Stay tuned for more circularity updates super soon.

5 Percent of textile-to-textile recyclable fabrics is calculated by total fabric yardage for apparel and upper fabric yardage for shoes YTD. This excludes all deadstock materials.

According to the Environmental Protection Agency, the U.S. alone throws away over 13 million tons of textiles and footwear a year, most of which sits in landfills indefinitely. We’re taking a big step towards developing a fully closed-loop system with RefRecycling, powered by our friends at SuperCircle.

Since our launch in March of 2022, more than 5,300 people have joined the circularity revolution, helping us divert 570 lbs of Ref from the landfill. To get in on it, drop off your pre-loved Ref–shoes, denim, sweaters, active, and outerwear–at any of our U.S. retail locations or request a shipping label online. As a thanks for keeping materials around, you’ll get Ref credit for every item you bring or ship back. Win-win.

We operate our own sustainable factory in LA where we produce some of our stuff and donate or recycle 100% of textile waste that's generated during the manufacturing process. The second part is pretty rare for our industry because the infrastructure just doesn’t exist in the U.S.

So we signed a letter of support for SB 1187. It’s a bill that will study and report on the feasibility of recycling fabric in partnership with garment manufacturers in LA and Ventura counties. Oh, and it was recently signed into law. It might not sound exciting, but it’s an important step in building a municipal system to responsibly divert textile waste from our landfills. Hot.

United Nations Sustainable Development Goals

The fashion industry has a major impact on the global economy and the environment. That’s why we aligned our sustainability framework with the United Nations Sustainable Development Goals (SDGs) to make sure we’re tackling the most important issues like climate change and economic inequality.

Progress SDGs: 12 Responsible Consumption & Production, 15 Life on Land