Sustainability Report Q3 2022

Q3 2022

THE SUSTAINABILITY REPORT

Oversharing is kind of our thing. While most big companies share quarterly earnings reports, we think we should all be accountable for more than that. So we tell you more than you’ve ever wanted to know about your clothes. Here’s an update on what we’ve been up to this quarter in our four main areas of sustainability: People, Product, Planet, and Progress.

People

There are a lot of awesome people behind our clothes, and we’re responsible for ensuring safe, healthy, and equitable working conditions for all of them. We’re committed to being people-focused and will continue to grow and evolve our work in this area of sustainability. Because who makes your stuff, and how they’re treated, matters a lot.

Purpose & Impact

Every single person at Ref helps drive our mission forward. So in Q3, we introduced a monthly training course to help all new hires find their own personal mission and think about how it connects to our work at Ref. They also work with their manager to identify how they can make an impact in their first six months on the job. This approach helps us measure performance beyond a traditional definition, by truly integrating sustainability in everyone’s work.

Taking action

The 2022 U.S. midterm elections are coming up. Voter turnout is usually super low for these, which can lead to small, non-representative groups of Americans making big decisions on issues that affect all of us. There’s also tons of stuff happening at the local level that matters. So we’re getting out the vote in our Los Angeles-based headquarters, and we want our customers everywhere to do the same.

We’re encouraging all Ref employees to check their voter registration status through I am a voter, learn what’s on their ballot using guides like Ballot Ready, and participate in volunteer opportunities like writing postcards that support Reclaim Our Vote, a non-partisan voter outreach campaign. And we always give employees time off to vote and volunteer.

If you’re not a Ref employee, we’ll see you here:

Getting Stuff Done, Election Edition (A great place to learn from voting pros who are getting stuff done)

We believe in prioritizing people and the planet, and voting is a pretty easy way to do both.

Our Partners

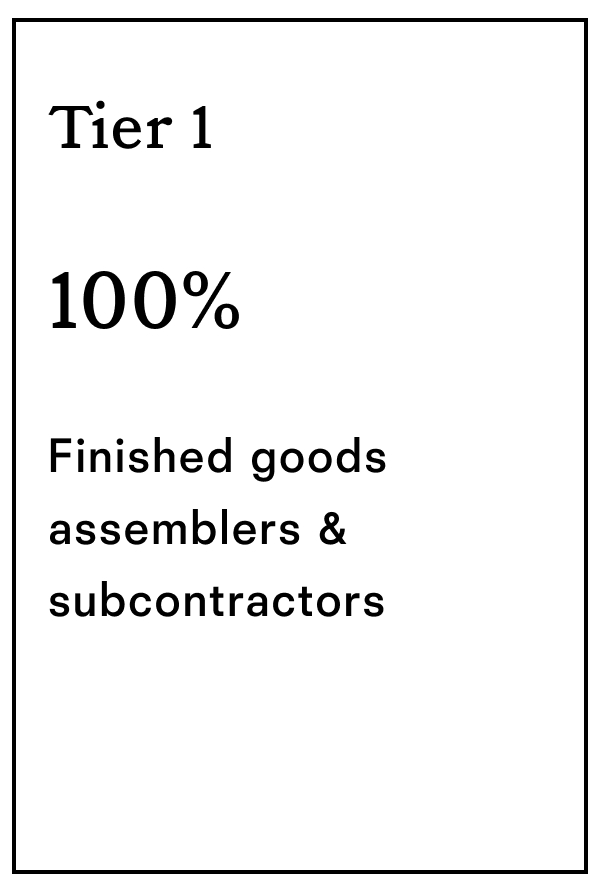

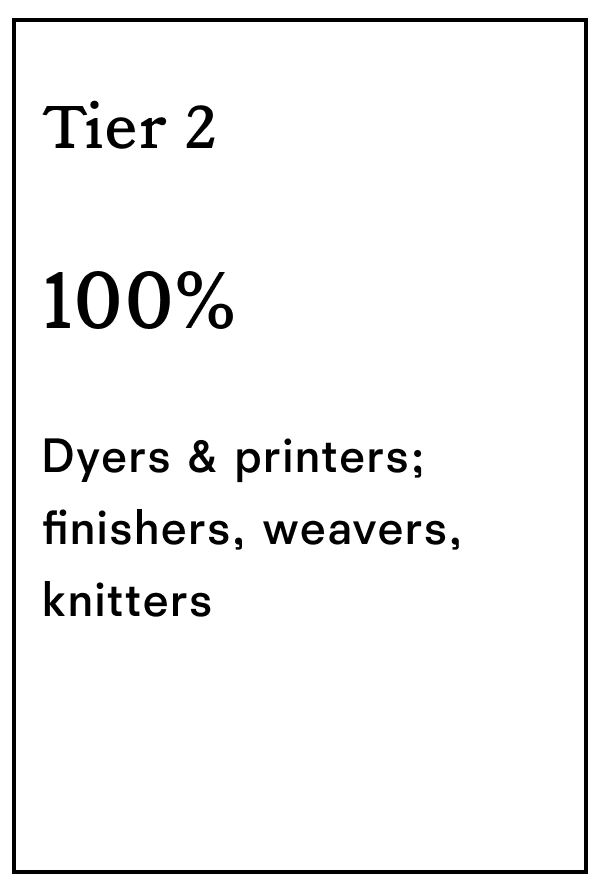

Throughout our supply chain, we work with incredible partners who share our values of accountability, transparency, and sustainability. Nobody’s perfect, but we’re working towards it and prioritizing transparency every step of the way. We require all our direct cut, sew, and finish manufacturing partners to adhere to our Code of Conduct1 (basically our requirements for ethical operations) to ensure fair labor conditions and fundamental labor rights. These include prohibiting child and forced labor, implementing health and safety protections, and meeting or exceeding legal minimum requirements in the locales where they work.

Our suppliers participate in independent, third-party social assessments to ensure fair, safe, and healthy working conditions and progress over time.

→ The process

1 Our Code of Conduct references the FLA Workplace Code of Conduct, which is based on International Labor Organization (ILO) standards and internationally accepted good labor practices.

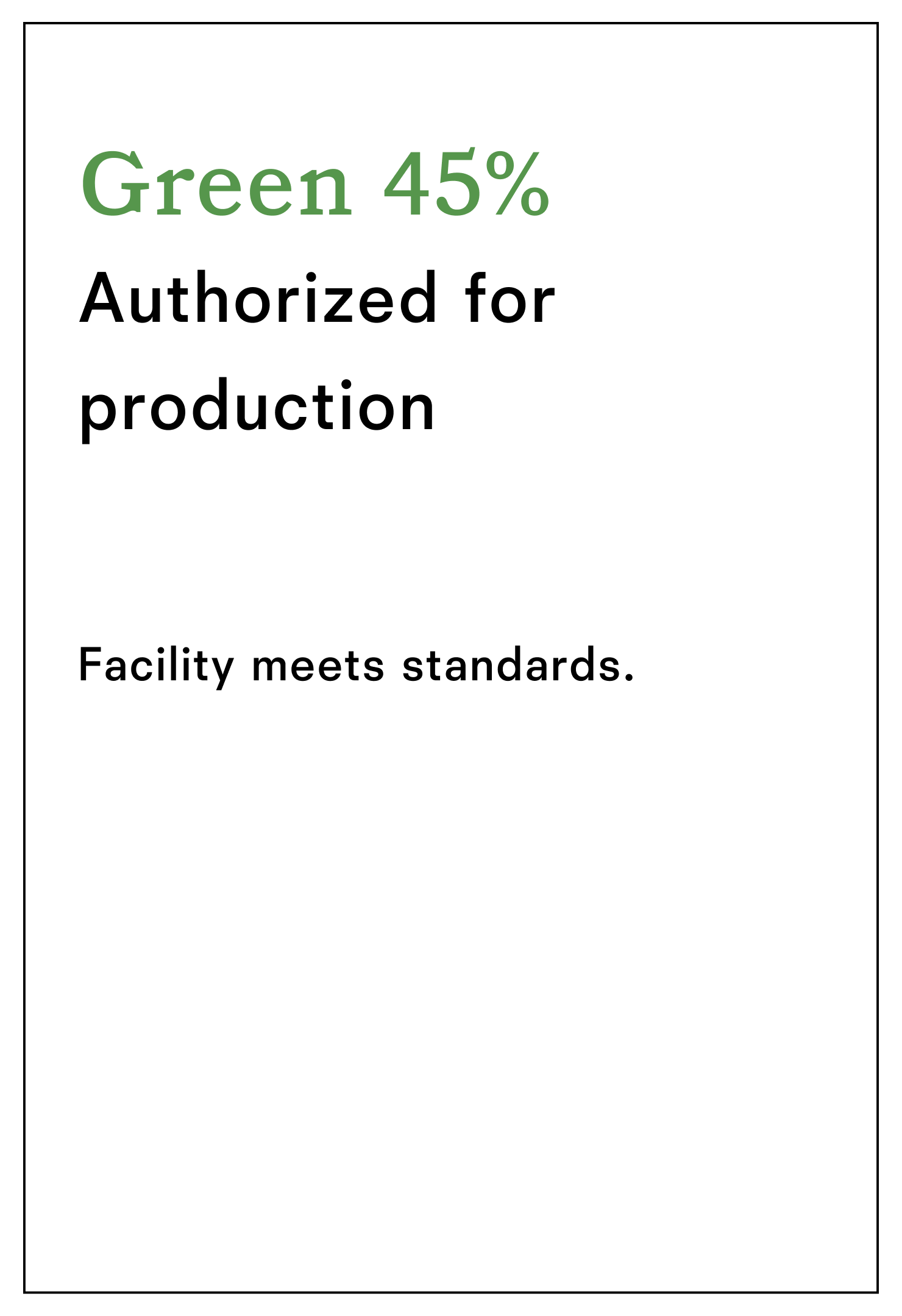

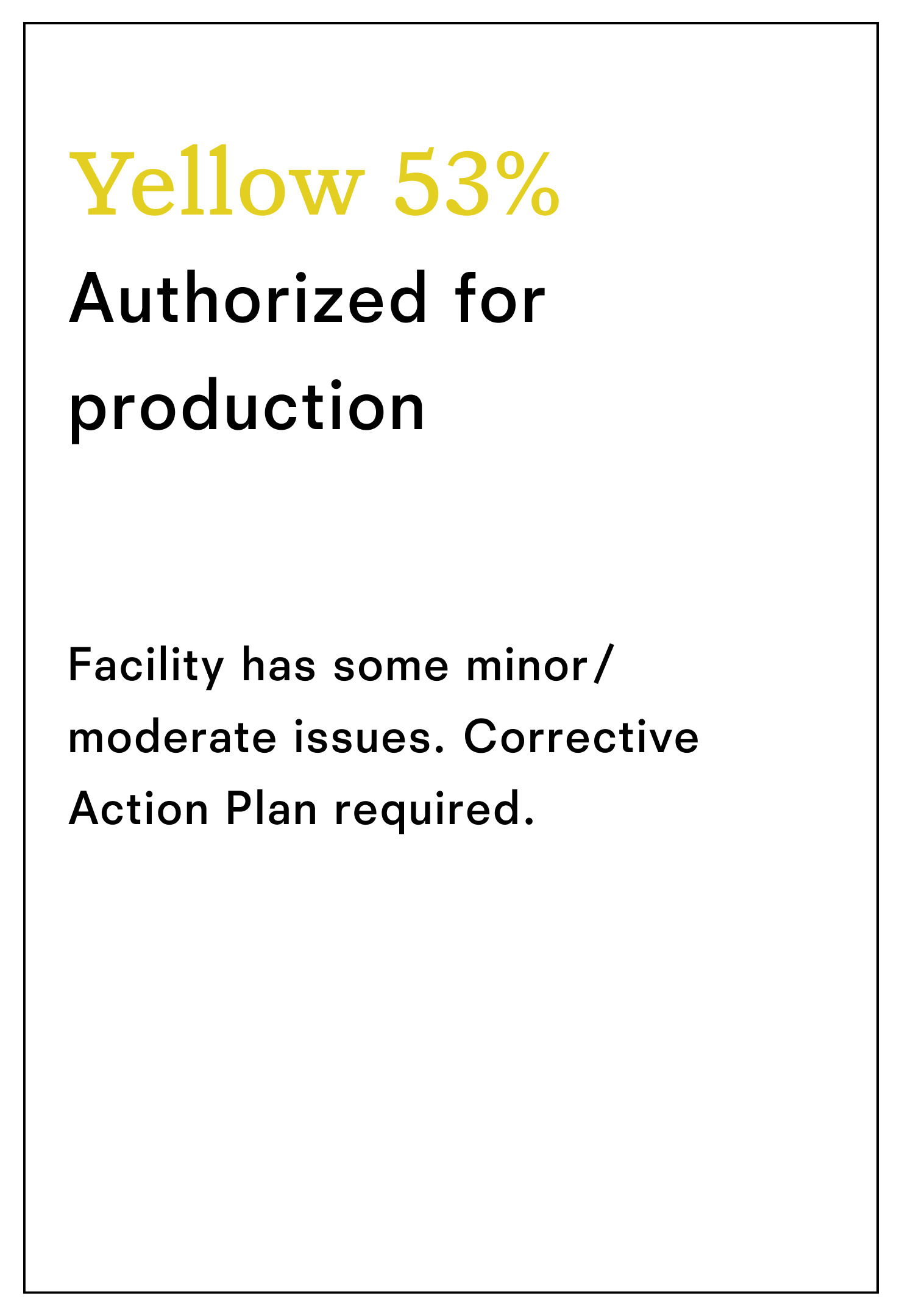

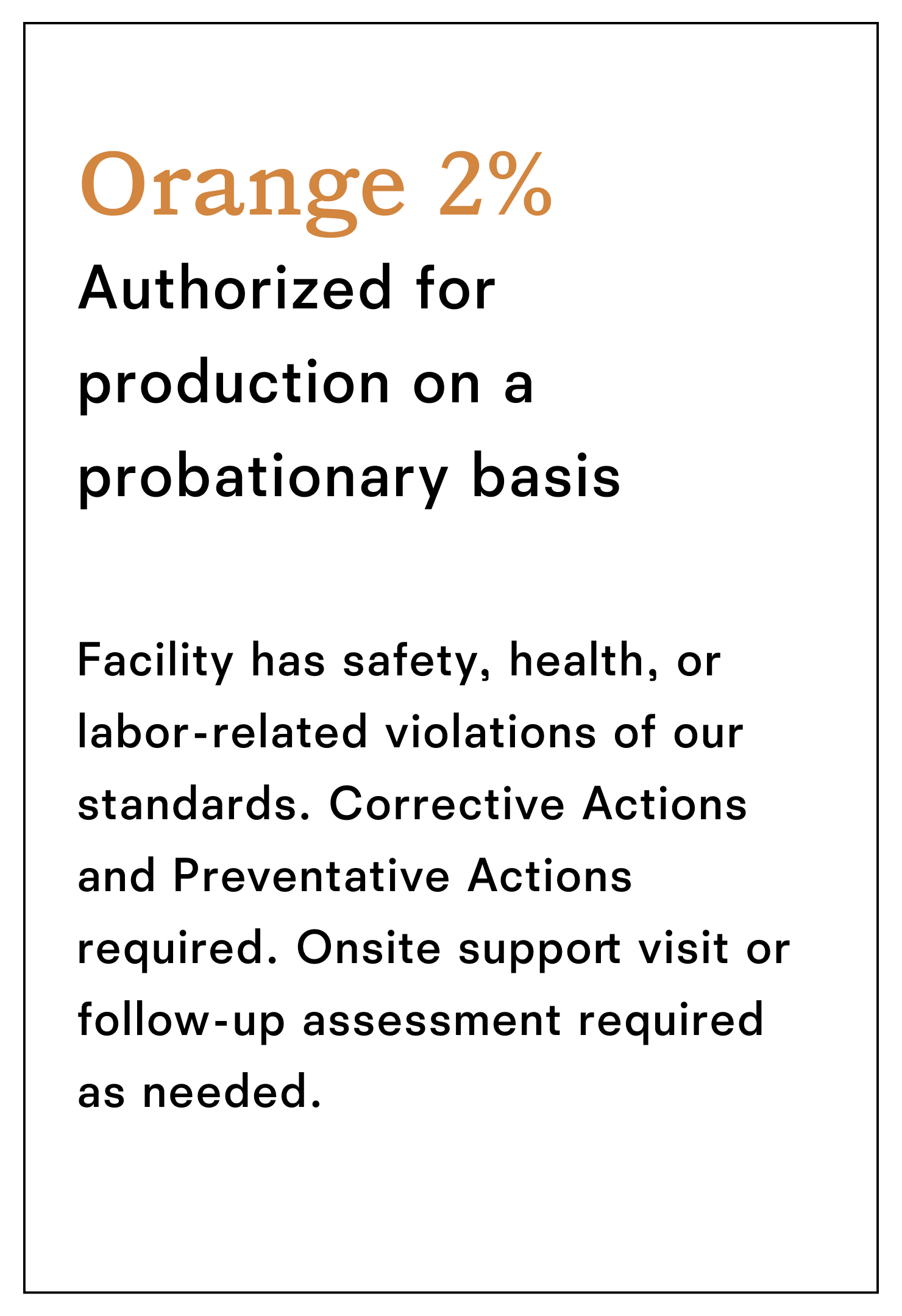

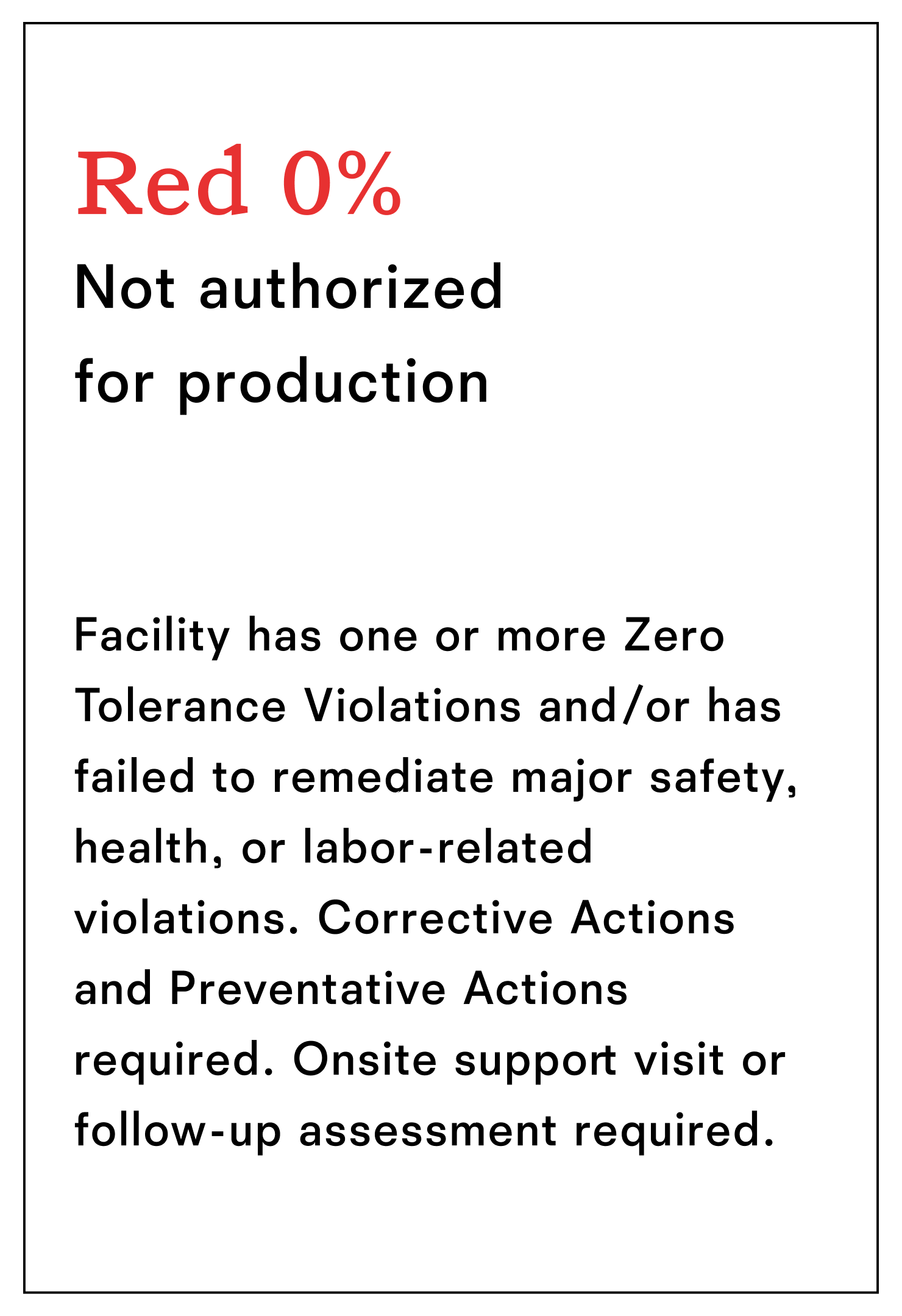

We use a color-coded rating system for our supplier audits. Our goal is to maintain a “Green” or “Yellow” rating for 95% or more of Tier 1 facilities (so our finished goods assemblers and contractors). While some of our suppliers are in the Orange tier, we work with them to find solutions so we can maintain relationships and influence better practices.

Diversity, equity, inclusion & belonging (DEIB)

This quarter, we continued our focus on building new processes and tools that support our recruiting efforts, as well as adding new internal training, education, and awareness.

Product

Your clothes go through a lot before they make it to you. We do the heavy lifting behind the scenes and focus on things like traceability, fiber standards, and clean chemistry. This lessens the environmental and social impacts of our stuff and lets you wear your values.

Cuter than it sounds

Weddings can be a lot. Besides all the emotional stuff, they can have big carbon footprints and the garments are often only worn once. We’ll never say ‘yes’ to that kind of dress.

So, this quarter we introduced two bridal collections featuring one of our favorite fabrics: deadstock.

Deadstock is old, leftover, and over-ordered fabric from other designers and fabric warehouses. We give verified deadstock an A rating in our Ref fiber standards because it allows us to reuse and divert these materials from the landfill and into your closet–or down the aisle. Sticking to our highest-rated fibers, like deadstock, is key to keeping us on track to achieve our Climate Positive and circularity goals.

Almost perfect

FYI, virgin cashmere has a giant carbon footprint. And even though cashmere represents less than 1% of the material we purchase, it accounts for almost half of our footprint due to its high carbon intensity. That’s not cozy, and we’re doing something about it.

As we work towards achieving climate positivity and reducing our sourcing footprint, we’ll be eliminating virgin cashmere. We’re not there yet, but this quarter, we launched our most sustainable cashmere yet.

It’s fabricated from 90% post-industrial recycled cashmere that comes from fiber spinning waste. We blend back into a luxury yarn instead of sending it to the landfill, then we combine it with 10% virgin cashmere (to maintain the fabric’s stability and strength) that comes from goats raised under the highest standards of animal welfare with low-impact grazing practices.

We haven’t perfected it yet, but our new yarn has 87% less of the carbon impact than conventional cashmere and 100% of the cuteness.

Born and raised in CA

We’re super excited to announce our membership in the California Cotton & Climate Coalition–AKA C4. You’ll see Ref styles made with the Climate Beneficial™, California-grown cotton, early next year. Through this first-of-its-kind coalition, we’re teaming up with like-minded brands, farmers, and researchers to collectively demonstrate the positive impact of regenerative farming practices–like better soil health, biodiversity, water retention, and more prosperous farming communities. Also, by sourcing Climate Beneficial™ cotton directly from the farmers in California’s Central Valley, we’re sharing the financial risk that can come with regenerative practices, and making it a more accessible path for all farmers.

We’ll be sharing more about our work with C4 soon and as we launch the styles in 2023. Stay tuned.

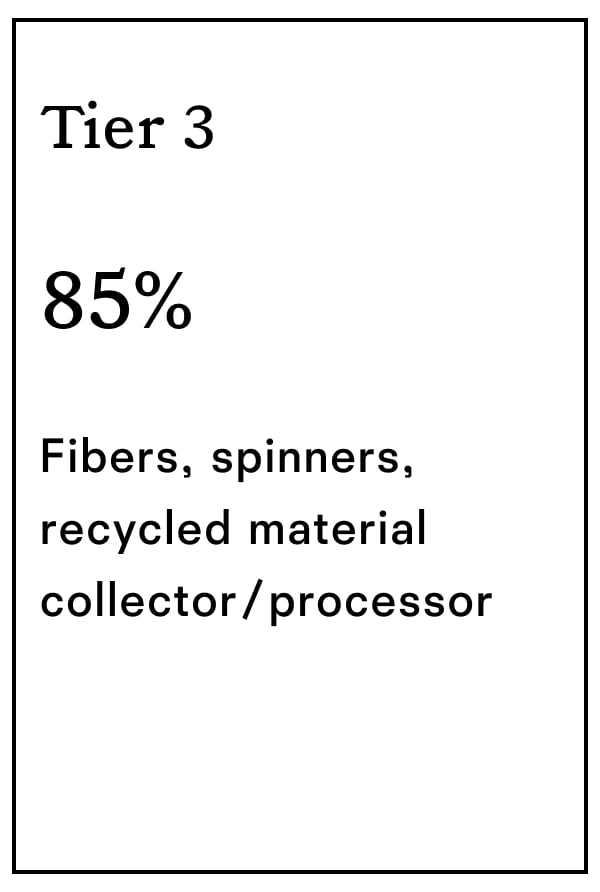

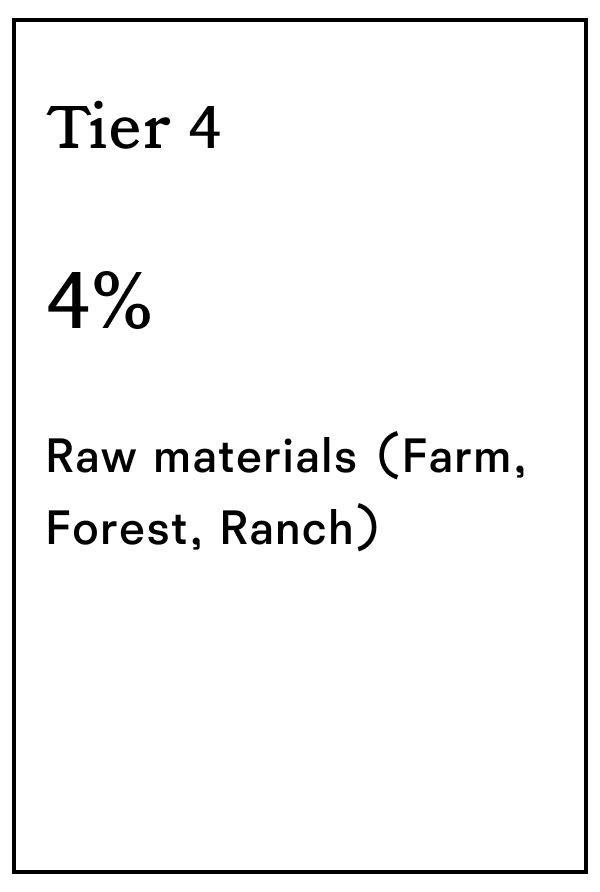

TRACEABILITY

Traceability is about knowing exactly where our stuff comes from. We want to be able to answer “who made our clothes” at every level of the supply chain.

Our goal is to reach 100% traceability1 down to the farm level for all of our animal-derived materials by 2025. Supply chains are complex, so we’re focusing on building relationships from the ground up and digging deeper into where our stuff is grown so we can take full accountability.

1 Traceability is calculated by total fabric yardage for apparel and by upper fabric volume for shoes YTD. This excludes all deadstock materials.

Here is where we made our stuff so far this year:

We’re committed to making clothes with a smaller environmental impact in places that treat workers well. We provide resources and support to help our partner factories align with our goals, achieve our standards, and grow with us.

→ Learn more about our factories

Los Angeles |

30.73% |

China |

54.72% |

Turkey |

8.63% |

Brazil |

3.85% |

Mexico |

1.58% |

India |

0.39% |

Indonesia |

0.08% |

Vietnam |

0.01% |

*Based on % volume shipped YTD

HIGH STANDARDS

Up to 2/3 of the environmental impact of our stuff happens at the raw materials stage—before the clothes have actually been made.

The materials we use play a major role in the total impact of our products. We have our own fiber standards that are as comprehensive as possible, taking into consideration water input, energy input, land use, eco-toxicity, greenhouse gas emissions, human toxicity, availability, and price. We also look at garment care implications like microfiber shedding. We’ve updated our fiber standards to include a few new fibers and more of the stuff we use in our shoes. Our goal is to have 100% of our fabrics be from recycled, regenerative, or renewable materials by 2025.

94% of our fabrics meet our A/B ratings, and 73% are from recycled, regenerative, or renewable materials3

→ Learn more about Ref fiber standards

Our highest fiber ratings are basically the best materials around that we want to use all the time. But, to meet our Climate Positive and circularity goals, we’re getting even more specific about what we use to make our stuff. By 2025, we want 100% of our fabrics to be from recycled, regenerative, or renewable materials. It means getting rid of some of our more traditional fibers, but it’s worth it to keep our stuff as sustainable as possible.

3 Fiber performance is calculated by total fiber volume usage YTD. Leather and deadstock are measured by total material volume usage. Percentages have been rounded up.

3 Percent of clean chemical certifications or ZDHC MRSL conformance of

Level 2 and higher for dyers, tanneries, and printers is calculated by total fabric yardage for apparel and upper fabric volume for shoes YTD. This excludes all deadstock materials.

Clean Chemistry

87% of our dyers and printers have a clean chemical certification4

BTW, this is almost double than what we reported last quarter–a big step in our clean chemistry strategy. We’ve been working with one of our main mill partners for several years to get bluesign®-certified, and this summer they made it official. We love working with partners, like this mill and others, who are committed to doing better and growing with us.

We partner closely with our printers, dye houses, and tanneries to ensure they are using chemical, water, and energy resources responsibly when making our stuff because we want our products to be safe for everyone and everything they touch. We joined bluesign® as a system partner in 2021, and with their help, we’re assessing our supply chain to see how we can best meet our clean chemistry goals. We are aligned with the ZDHC–which stands for the Zero Discharge of Hazardous Chemicals. They’re an industry collective dedicated to comprehensive and effective chemical management in the production of textiles. Our goal is to have 100% of our materials come from suppliers with clean chemistry certifications or Level 2 ZDHC compliance by 2025.

4 Percent of clean chemical certifications or ZDHC MRSL conformance of Level 2 and higher for dyers, tanneries, and printers is calculated by total fabric yardage for apparel and upper fabric volume for shoes YTD. This excludes all deadstock materials.

Planet

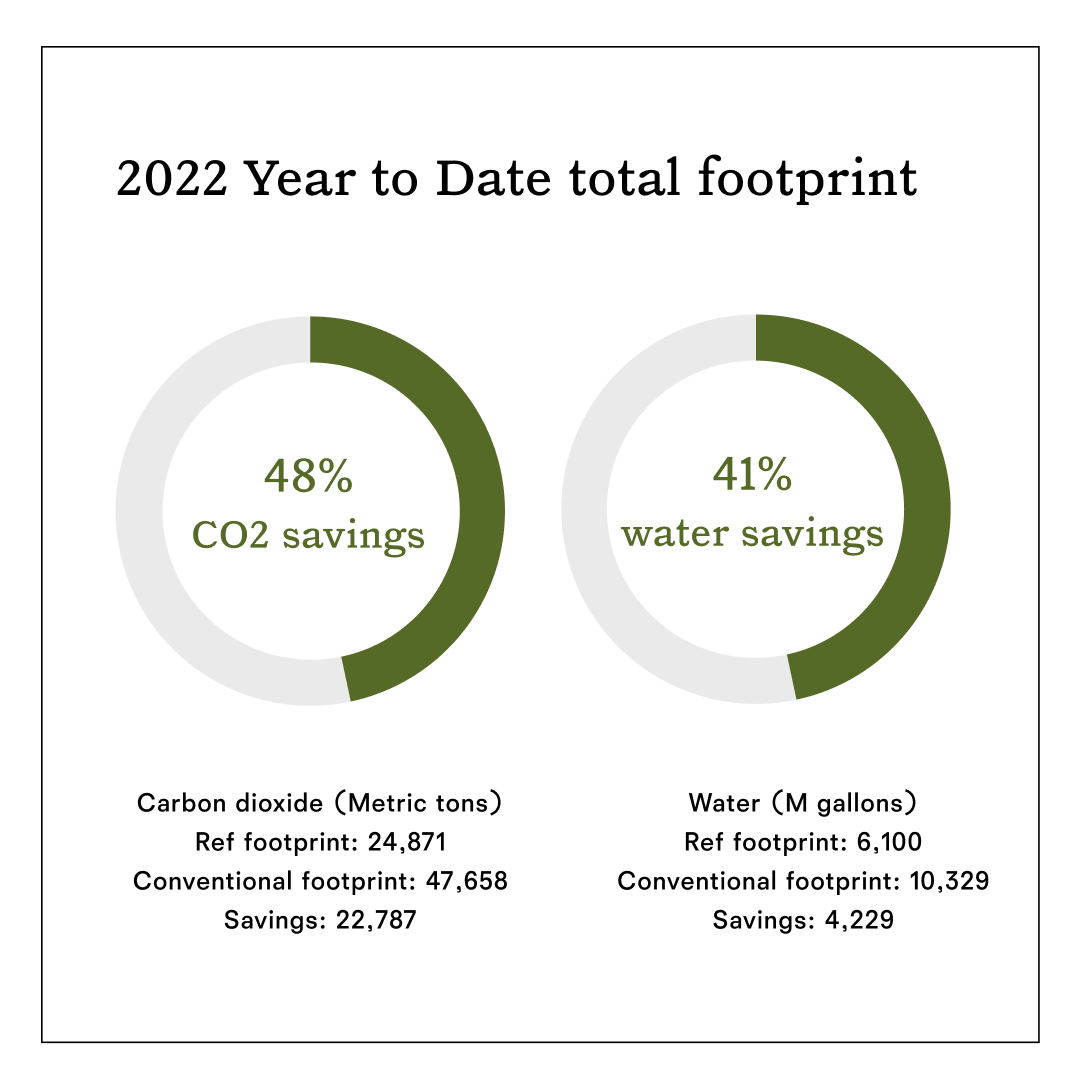

Making clothes has a big impact on people and the planet. We keep our true costs in mind when making any decision by tracking our product and company-wide environmental footprint.

Not just neutral

We are a Climate Neutral Certified company, which means we partner with Climate Neutral each year to measure our carbon emissions, offset 100% of our footprint, and work on reducing our emissions.

The fashion industry is responsible for an estimated 4-8% of global carbon emissions and is on track to double that by 2050. That’s why we made a commitment to be Climate Positive by 2025. We’re defining this as meeting science-based reduction targets and removing more emissions than we produce5.

Here are our official science-based targets:

We commit to reduce absolute scope 1 and 2 GHG emissions by 42% and scope 3 emissions by 48% per value added by 2030 from a 2021 base year.

Basically, as we grow, we’ll work to cut our emissions by about half across our operations and within our supply chain..

Travels well

In our Climate Positive Roadmap, we shared that the transportation of our raw materials to our factories and finished goods to our warehouses, retailers, and customers takes a lot of fuel, and represented around 20% of our total emissions in 2021. To move all of this around the world and to you on time, we use air shipping for about 40% of our stuff. But we need to fly a lot less

if we want to hit our carbon reduction targets–air transport is around 20-30x more carbon-intensive than using a cargo ship. We need to start moving as much of our stuff via ocean, ground, or carrier pigeon transport as possible.

So we kicked off a task force that includes members from our Supply Chain, Merchandising, Planning, Operations, Design, Tech, and Sustainability teams. We are working on better ways to refine our data and to create innovative solutions that balance the business needs for flexibility, quality, and sustainability. For instance, since we like short lead times, we’re looking for other places in the product life to save time and make up for longer transit cycles. Plus, we’re finding specific product categories or collections that we can plan on a different calendar.

FACTORY FORWARD

Approximately 2/3 of our total carbon footprint comes from our supply chain. So reaching our Climate Positive goal will require influencing real action within our supplier relationships more than anything else. We’ve partnered with the Apparel Impact Institute (Aii), a non-profit that works to identify, fund, and scale proven environmental impact solutions in the apparel and footwear industries, and South Pole, a company that repowers supply chains through the development and implementation of emission reduction strategies, to work with Reformation suppliers in a new Renewable Energy Transition Program.

It’ll help suppliers strengthen their environmental management systems, increase resource efficiency, and transition energy sources to renewables like solar and wind.

A third of our production already happens in Factory Forward facilities.

They’re creating roadmaps to reduce their energy use and implement effective renewable sourcing strategies, like the purchase of Renewable Energy Credits (REC) and Energy Attribute Credits (EAC).

5 Targets are considered “science-based” if they are in line with the level of decarbonization required to keep the global temperature increase below 1.5°C compared to that of pre-industrial temperatures, as described by the Intergovernmental Panel on Climate Change (IPCC). It’s a lot of info, but the good news is our targets are officially confirmed and validated by the Science Based Target Initiative.

6 The carbon intensity of our product KPI is calculated by dividing our total RefScale footprint year-to-date by the number of units produced year-to-date. Our total RefScale footprint is calculated using RefScale, which provides a carbon footprint for each of our styles, which is then multiplied by the total number of units produced per style.

Progress

We have a lot of work to do to create a truly circular fashion system. In order to push sustainability forward, we challenge ourselves and don’t shy away from our problems. We’re committed to investing in the future, and we’ll always be transparent about our progress.

Sorry, we faked it

Maybe you saw our fake show during fashion month featuring ‘90s supermodel and environmental activist Carolyn Murphy. We have a bunch of reasons why we didn’t put on a real show.

Typical collections take 12-18 months to show up in your closet. That kind of delayed timing doesn’t fit with our business model and it never will. We make stuff we know you want, when you want it by using some geeky data. We keep our quantities low and like to sell out, meaning less waste and unworn stuff, and more exclusivity for you.

This all helps us stay flexible so we can try out new, innovative materials (like our 90% recycled cashmere) and focus on other sustainable details like better packaging and making improvements in our supply chain.

In case you’re worried about reality, everything we used in our fake show had a lower environmental impact, was recycled, or reused by other productions. The clothes we showed were extra real and saved 42% on water and 33% on CO2 compared to conventional clothing.

Bye plastic

We’re also working on developing 100% plastic-free product packaging. One of our biggest challenges will be replacing our polybags, which we currently use to protect our products while they’re on the move. We’ve tried using compostable materials, but since composting in the U.S. isn’t widely accessible yet, we’ve switched to 100% recycled plastic bags with a biodegradable polymer (BDP) that allows them to break down in landfills. We also launched a program this quarter to collect our own business waste and use it to create new recycled polybags and we’ve collected around 6,000 lbs of polybag waste since July 1. So we can close the loop and cut waste while we work on getting rid of virgin plastic for good.

We get around

Circularity is all about designing out waste and keeping materials in use. Decisions at the earliest stages of making clothes affect their end of life, like how you’ll recycle it when you’re done wearing it. The technology and infrastructure exist to recycle some materials back into fiber, but it’s not yet available for everything. We’re setting a goal to have 100% of our fabrics be fiber-to-fiber recyclable by 2030 to motivate us to design using fabrics that have potential for circularity. We’re also building more partnerships with recyclers to make it easy to keep our stuff around.

15% of our fabrics are fiber-to-fiber recyclable7

7 Percent of fiber-to-fiber recyclable fabrics is calculated by total fabric yardage for apparel and upper fabric yardage for shoes YTD. This excludes all deadstock materials.

RefRecycling

The U.S. alone throws away over 16 million tons of textiles a year, most of which sits in landfills indefinitely. We’re taking a big step towards developing a fully closed-loop system with RefRecycling, powered by SuperCircle.

Since our launch in March, over 4,700 people have joined the circularity revolution. To get in on it, drop off your pre-loved Ref–shoes, denim, sweaters, and active–at any of our U.S. retail locations or request a shipping label online. As a thanks for keeping materials around, you’ll get Ref credit for every item you bring or ship back. By participating, you’ll also help us meet our commitment to design all of our stuff to be circular by 2030. Win-win.

United Nations Sustainable Development Goals

The fashion industry has a major impact on the global economy and the environment. That’s why we aligned our sustainability framework with the United Nations Sustainable Development Goals (SDGs) to make sure we’re tackling the most important issues like climate change and economic inequality.